Measured Energy Savings Mean Real Results for Pfizer Pharmaceutical

Puerto Rico-based Nemar Technology Helped Improve the HVAC System for Pfizer’s Manufacturing Facility by Sealing the Ductwork.

Thanks to generous tax breaks and an enthusiastic workforce, Puerto Rico has become an attractive destination for pharmaceutical companies expanding their operations. And while its beautiful landscape and generous financial incentives are a draw for some of the world’s largest drug manufacturers, the island’s high humidity rate requires constant vigilance for an industry where environmental control is essential for successful manufacturing.

Project Overview

- Building: Pfizer dry compress building

- Location: Vega Baja facility, Puerto Rico

- Customer: Pfizer Pharmaceutical (Facilities Staff)

- Aeroseal Contractor: Nemar Technology Group

- Goal: Improve AHU performance; Ensure an optimal HVAC environment for sufficient manufacturing conditions; Reduce energy use

- Before Aeroseal: 2,424 CFM of leakage

- After Aeroseal: 77 CFM of leakage

- Results: Achieved sufficient HVAC operations for manufacturing environment; Improved HVAC system performance; Effectively balanced the system; Saved $35K annually in energy costs

When Pfizer Pharmaceutical began work on a $100 million upgrade to its main manufacturing building in Vega Baja, Puerto Rico, keeping the indoor environment dry was not only a high priority, it was an imperative.

In an effort to ensure a proper indoor environment, Nemar Technology Group (NTG), an HVAC service company, wanted to ensure the ductwork serving the building’s 40+ air handing units was as airtight as possible. Initial problems balancing the new systems alerted NTG’s president Jose Hiraldo to the presence of leaks in the existing duct system. He knew that duct leakage was not only related to performance issues but that it would also affect energy costs and the HVAC system’s ability to properly control humidity.

Alerted to the problem, Pfizer brought in contractors to seal the ductwork by hand (e.g. mastic/tape). Unfortunately, gaining adequate access to hard-to-reach sections of the duct system was difficult at best. A lot of the ductwork was insulated and encased in metal sheeting. The demolition and repair associated with sealing this type of ductwork using hand sealing alone proved too disruptive and too expensive to implement. After several failed attempts at hand sealing, Hiraldo knew he had to find a better solution.

Hiraldo’s research lead him to Aeroseal’s duct sealing technology. If the duct sealing technology actually delivered as promised, then Pfizer would not only gain proper environmental control over its manufacturing facility but, according to Aeroseal, the company would save a tremendous amount in energy costs as well. Based on what they had learned, Pfizer decided to proceed with an initial pilot project focused on sealing the ductwork servicing one of the main manufacturing building’s HVAC systems, including a huge silica dehumidification unit. If the Aeroseal project was successful, then the dehumidifier would work more efficiently while, at the same time, cost less to operate.

“When it comes to energy savings, we’ve heard it all before,” said Hiraldo. “We wanted to make sure the savings were real and not just theoretical, and we knew that would require real before-and-after measurements rather than the simple modeling that is usually used to support savings claims.”

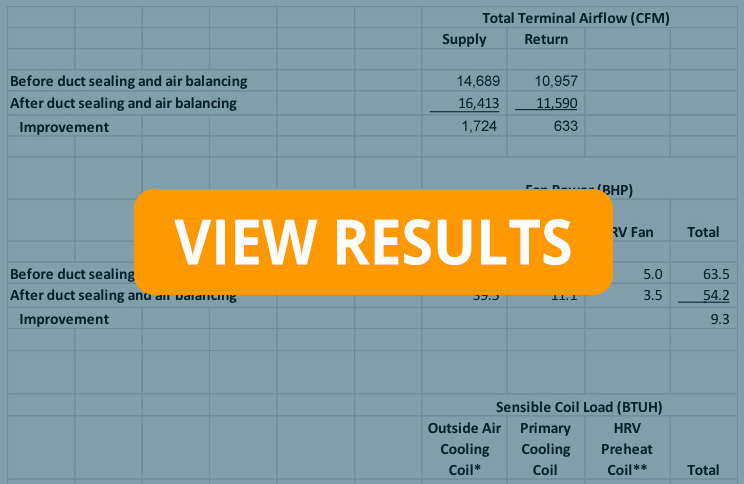

Exact measurements of the airflow delivered to the main manufacturing building and the energy used to run the HVAC system were taken before the sealing began. NTG measured the brake horsepower of each of the system’s three fans. They also measured the airflow across the system’s three cooling coils – the primary cooling coil, the outside air cooling coil, and the heat recovery system’s inlet air pre-heat coil – and calculated the sensible load on each coil at design conditions. Measurements indicated that the building’s terminal airflow was below the design value.

From equipment setup to actual sealing, the Aeroseal process took NTG two days to complete, followed by a repeat of performance measurements. Results showed a 97% reduction in leakage. Even after increasing the airflow to meet the building’s design amount, NTG calculated that the post-seal HVAC system generated nearly $35,000 in annual energy savings. It is expected that actual annual savings from this pilot project alone will exceed this amount when the reduction in sensible cooling load of the primary cooling coil and the reduction in latent cooling load of both coils are included.

“The results spoke for themselves.”

Edward Aviles

Project Engineer

Pfizer

“The results spoke for themselves,” said Edward Aviles, project engineer at Pfizer. “The aerosol duct sealing (method) was able to do what several attempts at manual sealing with mastic/tape could not – and it did it without the demolition or disruption that traditional sealing requires. Our goal was to get the air handling units operating at optimal efficiency, which it allowed us to do. The energy savings was certainly welcomed. We estimate ROI to be less than one year.”

We Can Help You Too.

To learn more about improving the heating/cooling comfort, indoor air quality (IAQ), and energy efficiency of your home or building, email us a message to info@aeroseal.com or give us a call 937-428-9300.