Florida Hospital Halts Spread of Airborne Infections Using Aeroseal

Nemours Childrens’ Clinic in Jacksonville, Florida sealed its air duct system using Aeroseal duct sealing to improve HVAC airflow and ensure germs are removed through the building’s exhaust and not recirculated through air leaks in ductwork.

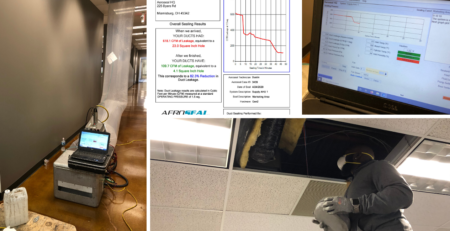

There were so many retrofits and extensions added to the ventilation system at Nemours Children’s Clinic in Jacksonville, Florida engineers couldn’t pinpoint their airflow problems. What they did know was negative pressure and inadequate ventilation throughout the more than 30-year-old building could contribute to the spread of nosocomial infections. Their first steps in taking control of the situation was to seal the duct leakage in the exhaust shafts located on each floor and in the main shaft running down the length of the 11-story building.

Project Overview

- Building: 11-story outpatient medical facilities located on the Nemours Childrens’ Clinic Jacksonville campus

- Location: Jacksonville, Florida

- HVAC Contractors: Carrier Corporation

- Aeroseal Contractors: Aeroseal Southeast

- Goal: Improve HVAC system airflow; reduce the risk of nosocomial infections from germs being distributed through leaks in HVAC ductwork

- Before Aeroseal: Total system leakage: 4,912 CFM

- After Aeroseal: Total system leakage: 723 CFM

- Results: Sealed ductwork to 85% leakage reduction; Stopped the spread of germs through duct leakage; Improve HVAC airflow throughout facility

Sealing the air duct system of the hospital building using Aeroseal took less than 30 days to complete. The difference it made to the efficiency of the exhaust system was immediate and obvious. With the ductwork’s leaks effectively sealed from the inside, engineers were able to accurately analyze the system and upgrade it with regulating dampers and other flow-adjusting technologies. Now the building’s exhaust system is optimized at all times. The bottom floors are as well ventilated as those on the top. Most importantly, the air being exhausted is coming from the rooms and common areas that need it; contaminated air is being removed from the building. As an added bonus, the clinic is able to run its exhaust fan at a fraction of the power that was previously needed, saving the clinic substantially on its energy costs.

Testimonials

Derrick Rhodes, President, Aeroseal Southeast: “In order for a hospital to be clean, you have to manage the building’s airflow. By sealing the exhaust shafts using Aeroseal, we ensured that the right amount of stale and potentially infectious air is being adequately and continually removed from the building.”

Chuck Boynton, Areas Project Manager, Carrier Corporation: “Exhausting air from a leaky ventilation shaft is like using a straw with holes in it. No amount of force is adequate to effectively ventilate the bottom floors of the building. Now, after sealing the leaks with Aeroseal, all floors are getting the ventilation they need. As a side benefit, we were able to dramatically reduce the speed of the exhaust fan, which has resulted in substantial energy savings for the clinic. With the ductwork effectively sealed, we are now able to take additional steps to optimize the entire exhaust system.”

Learn How We Can Help

To learn more about improving the comfort, indoor air quality, and energy efficiency of your building, email us at info@aeroseal.com or give us a call at 937-428-9300.