Pensacola Christian College Fixes HVAC Issues Using Aeroseal

University Turns to Aeroseal Duct Sealing to Improve Campus Housing During a Renovation Project; HVAC Performance Improves too.

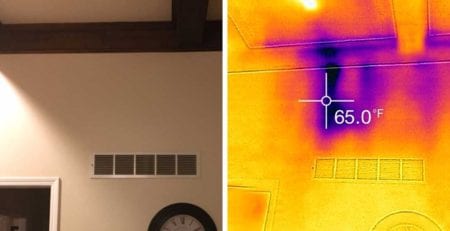

In the coastal town of Pensacola, Florida, the key to fighting humidity and excessive moisture is ensuring proper building ventilation. Therefore, when administrators at Pensacola Christian College decided to renovate Campus House, the college’s three-story dormitory, they knew they needed to get proper exhaust levels from the 30 risers leading from the buildings’ various bathrooms to the attic. As it turned out, air leaks in the ductwork were making it impossible for the large attic fans to draw sufficient air through the system. After year-long efforts of hand sealing, mastic/tape by itself failed to do the trick. Engineers considered adding auxiliary fans to each bathroom. Unfortunately, exorbitant labor costs, logistics, and concerns over excessive HVAC fan noise eliminated the viability of this approach as well.

Project Overview

- Building: Campus House; Pensacola Christian College

- Location: Pensacola, Florida

- Engineers: Premier Engineering Group LLC

- Aeroseal Contractors: Blackwell Htg. & AC

- Goal: Improve ventilation for college campus housing renovation

- Before Aeroseal: 1,252 total CFM of leakage

- After Aeroseal: 183 total CFM of leakage

- Results: Sealed ductwork to 85% leakage reduction; Improved ventilation for HVAC system

Since Aeroseal works from the inside of the ductwork to seal leaks, issues related to manually locating and accessing the leaks were reduced. A test project involving one of the risers also eliminated any concern that the aerosol-based duct sealant would interfere with HVAC equipment (e.g. fire dampers or other internal structures).

Over a period of several days, Aeroseal technicians were able to seal all 30 risers and reduce leakage by 90% or more. Where manual sealing failed, Aeroseal performed quickly and effectively. Accessing the existing shafts was accomplished without the need to demolish any of the building’s existing walls or other structures.

Since its initial use, Aeroseal technology has been recommended for additional campus renovation projects.

Testimonials

Eric Hendersen, Chief Engineer, Pensacola Christian College: “We were concerned about the possible effect that the Aeroseal sealant might have in and around the fire dampers, where much of the leakage was determined to exist. Our initial pilot project revealed that Aeroseal had virtually no negative effect on the dampers. The aerosol-based sealant sealed the leaks around the dampers but didn’t affect their functioning whatsoever. In the end, aeroseal made a big difference – sealing 80% to 90% or more of the leaks.”

Chuck Brown, Engineer, Premier Engineering Group, LLC: “After test and balancing (TAB) revealed how leaky the existing ductwork was, the college tried to manually seal the leaks found throughout 30 or so risers. Particular attention was paid to the gaps in and around the fire dampers and access doors. Unfortunately, the manual sealing didn’t really make much of an improvement. As an alternative approach, we tried Aeroseal and it quickly sealed even the most inaccessible leaks. The results was an overall leakage reduction of about 85%.”

We Can Help You Too.

To learn more about improving the heating/cooling comfort, indoor air quality (IAQ), and energy efficiency of your home or building, email us a message to info@aeroseal.com or give us a call 937-428-9300.