Syracuse University Housing Qualifies for Energy Rebate with Aeroseal

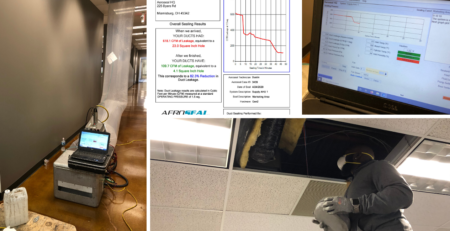

When building the new dormitory for Syracuse University graduate law students, general contractor Hayner-Hoyt Corporation was looking to meet high standards for energy efficiency. 10 CFM of air duct leakage or less – that was the goal. To qualify for a rebate under New York State’s NYSERDA program for new construction, they would have to

exceed SMACNA standards, surpass LEED for Homes certification criteria and meet that 10 CFM per floor requirement. There was only one possible way they could do it – Aeroseal.

Project Overview

- Building: Syracuse University Campus West

- General Contractor: Hayner Hoyt Corp.

- HVAC Installation: Century Heating & AC

- Goal: Score $170,000 rebate under NYSERTA; requiring air duct leakage of 10 CFM or less

- Before Aeroseal: Average 120 CFM of leakage

- After Aeroseal: 10 CFM of leakage or less

- Results: Even after meticulous construction, the use of Aeroseal was the only solution to meeting new stringent duct leakage requirements

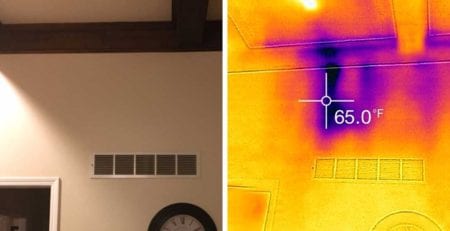

The new four-story building includes 200 graduate student apartments. Its massive ductwork consists of seven individual rooftop energy recovery ventilation systems. The bathroom exhaust and outside air supply ductwork extended horizontally and vertically to each water-source heat pump HVAC unit and bathroom. Each shaft is completely sealed in sheetrock and protected with fire smoke dampers.

Knowing from the start that it would need to meet stiff requirements for air duct leakage, Century Heating and Air Conditioning was careful when originally constructing the duct system. Still, post-construction tests showed unacceptable levels of leakage when work was first completed. After weighing various options, Century determined Aeroseal was the only

viable solution. The company decided to invest in training and learned to apply the duct sealant themselves. Once started, work on the entire building structure was completed in a few short days.

Testimonials

“Aeroseal provided the lowest leakage rates we’ve seen for any duct system at anytime, anywhere. Energy conservation guidelines are only getting tougher and the most stringent requirements today will soon become standards for all future buildings. We’ve found Aeroseal duct sealing to be an absolute necessity to meet today’s toughest energy conservation programs and I believe the technology will soon become a standard practice used in all new constructions.”

David Wildrick

Engineer

Century Heating and Air Conditioning

“As energy efficiency standards become increasingly stringent, we will need to turn to new technologies like Aeroseal. It was a game-changer for this project and a key to our ability to meet the NYSERDA requirements.”

Sam Doss

Project Manager

Hayner Hoyt Corporation

“Century Heating And Air Conditioning realized that Aeroseal is quickly becoming a mainstream solution for energy efficient construction and will play a vital role in helping contractors meet the ever-increasingly stringent standards for compliance. The company first used Aeroseal to qualify for a substantial rebate program and is now considering it for every job they do.”

Robert Seals

Aeroseal, LLC