Hilton Hotel, Saudi Arabia Advances Energy Efficiency Using Aeroseal

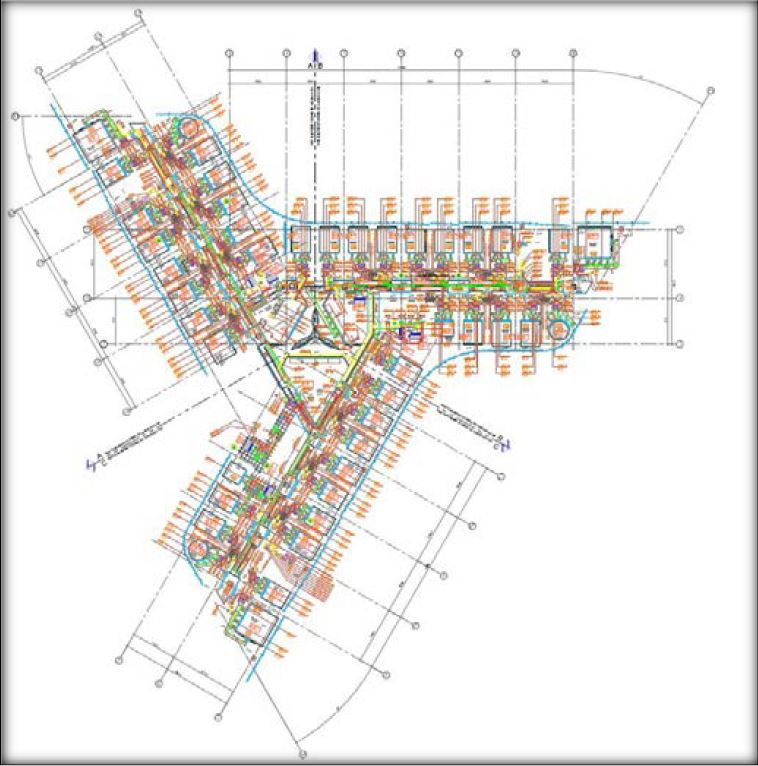

When it opened to the public in 2018, the Hilton Riyadh Hotel in Saudi Arabia was one of Hilton Hotel’s most iconic properties in the world. The massive luxury hotel and residence complex has 866 guest rooms as well as four restaurants, including a roof garden cafeteria, a business center, a health club with an indoor swimming pool, and a 1,750 seat ballroom. The total built-up area for the complex is 220,000 M2.

Project Overview

- Building: Hilton Riyadh Hotel and Residences

- Location: Riyadh, Saudi Arabia

- Aeroseal Contractor: Advanced World Trading (AWT)

- General Contractor: Al Latifia

- Goal: Meet ventilation codes for exhaust duct leakage; Improve energy efficiency of HVAC system

- Before Aeroseal: 33,089 CFM of total leakage

- After Aeroseal: 1279 CFM of total leakage

- Results: Sealed ductwork to 95% reduced leakage, which contributed to annual energy savings close to SAR 215,000

A soft launch was scheduled for Summer 2018. However, duct leakage was lurking in some of the exhaust shafts of the 20-story and 12-story buildings that would delay project completion.

In July 2017, general contractor Al Latifia turned the project over to its commissioning consultant (UCS) and an air balancer (Team Arabia) to begin commissioning of the ventilation system and fresh air makeup in the guest rooms.

The commissioning was done in order to meet the required ventilation (and duct sealing) codes to complete the project and hand it off to the Hilton for occupancy.

Exhaust leakage levels determined that duct sealing was needed. Unfortunately, there was limited access to the ductwork for sealing the air ducts by hand (e.g mastic, tape).

The commissioning team was intrigued by Aeroseal as a possible solution to their problem. “A solution that only clings to and fills the holes without coating the inside of the ductwork. How can this be possible?” said Muthafar Emeish, commissioning team leader for UCS. Working with local Saudi Arabian Aeroseal service provider Advanced World Trading (AWT), Aeroseal duct sealing was proposed as the solution to Shakir Hamdi, MEP Project Director at Al Latifia (general contractor for this project).

“When Al Latifia brought the idea to me, I had never heard of Aeroseal,” said Irshad Zahid, Mechanical Engineer for Omrania. “But the shafts were fully enclosed in masonry. Although there were access panels, it would have been extremely tedious work to get inside and try to seal all the joints by hand.” Zahid continued, “Manpower costs are relatively low here, but in this case, time was the most valuable commodity. We had a specific timeline to meet and would have had to call in a very large crew to even attempt manual sealing.”

“I found the Aeroseal process to be very effective!”

Irshad Zahid

Mechanical Engineer

Omrania

Game-Changing Duct Sealing Results with Aeroseal

Using Aeroseal technology to seal the ductwork provided significant advantages over using hand sealing methods alone. Applied as an aerosol mist, the sealant is blown into the interior of ductwork that has been temporarily segmented into specific sections. Not coating the entire inside walls of the air ducts, the sealant particles remain suspended in air until they are drawn to the various leaks. The particles then stick to the edge of the leak and then to other particles until the entire hole is completely filled from the inside.

AWT mobilized its project team and set to work on sealing one single section of riser at the hotel. The results of the pilot sealing project were impressive. “I saw it work with my own eyes,” said Fadi Osiali, senior mechanical engineer from Team Arabia. “I punched several holes in the ductwork and saw them filled,” echoed Emeish from UCS.

With the pilot project successful, the go-ahead was given for AWT to seal the rest of the hotel’s 70 risers (ductwork ranging in length from 60 to 180 meters) to improve exhaust duct leakage and meet duct sealing codes, guaranteed. At the same time, a thorough duct inspection was conducted using unique robots, and AWT recommended that cleaning and polishing of some of the ductwork also be performed.

A large team of project leaders, technicians and assistants was assembled using resources from both AWT and Al Latifia. Sealing began in early March 2018. Two separate Aeroseal machines were in operation around the clock until completion of the project in only eight weeks. After sealing, Team Arabia and UCS completed all the final verifications on all 70 risers successfully.

See the award-winning Aeroseal technology featured at the International Builders’ Show.

At long last, the massive project could be handed over to the Hilton. Tarek Khalifa, Riyadh Hilton’s assistant chief mechanical engineer, has a unique perspective on the successful project. “I started out working with Al Latifia during the construction phase and was one of the first to witness the duct leakage problem,” remarked Khalifa. “The hotel’s HVAC systems were producing the designed cfm – but the air was not being delivered. Now, thanks to Aeroseal, the systems are performing as designed.” Khalifa also happily reported, “The pre-opening Hilton team will take over in the presence of the contractors on July 1, to begin preparations for the Grand Opening planned for October 2018.”

Testimonials

“The entire Aeroseal team was very proactive and always pushing to solve the problem in a timely manner. We already have another project (hospital) on which we are planning to use Aeroseal in the future.”

Shakir Hamdi, MEP Project Director, Al Latifia

“I found the Aeroseal process to be very effective! It eliminated more than 90% of the leakage, which is quite a good percentage. Many times, leakage is pushed under the carpet, especially when it comes to exhaust. But Aeroseal was able to meet and exceed our very strict test standards.”

Irshad Zahid, Mechanical Engineer, Omrania

“Everyone was surprised at results that were achieved with Aeroseal. The expedited process was a big advantage. It is a very effective technology, and we are happy to have found it. We will definitely consider it for future projects.”

Muthafar Emeish, Commissioning Team Leader, UCS Universal Consultancy Services

“The difference in airflow before and after Aeroseal was staggering. The final results demonstrated really good readings and flow. We can definitely see and feel the improvement. We were skeptical in the beginning, but now we know Aeroseal will work.”

Fadi Osiali, Senior Mechanical Engineer, Team Arabia Test and Balance Contractor

“Aeroseal proved to be a very innovative solution for our problem. I was very happy with the immediate reduction in leakage. I have already had many inquiries about the Aeroseal process and AWT. We were pleased with their work and are hoping to use them for ongoing exhaust cleaning and maintenance at the hotel.”

Tarek Khalifa, Assistant Chief Mechanical Engineer, Hilton Hotel

We Can Help You Too.

To learn more about meeting duct sealing codes in your area, plus improving the heating/cooling comfort, indoor air quality (IAQ), and energy efficiency of your home or building, email us a message to info@aeroseal.com or give us a call 937-428-9300.