Gen2.1

Engineered & Designed for Commercial HVAC

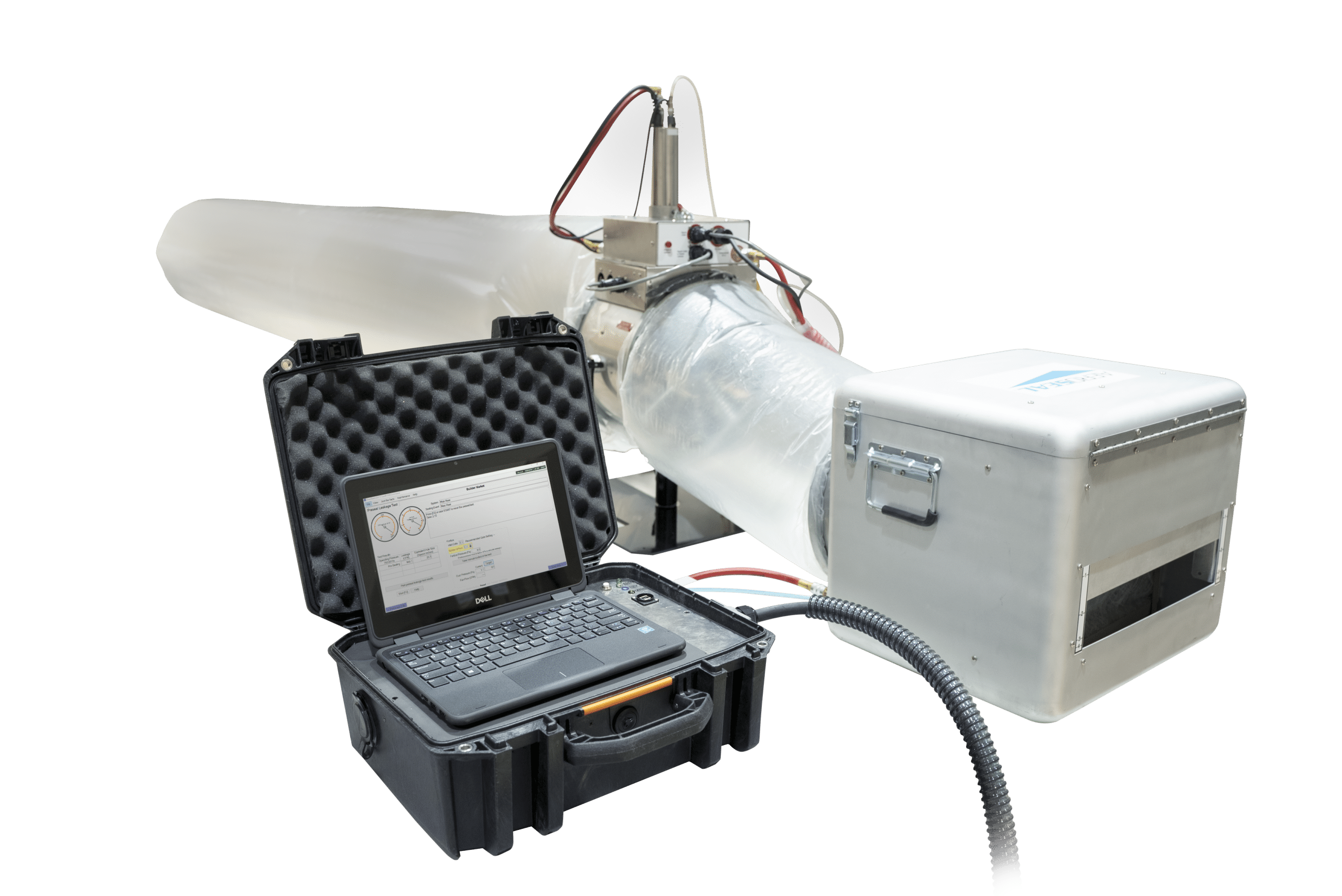

Gen2.1

The Gen2 is offered as a modular system, complete with interconnecting cables, computer suitcase containing the commercial version of the “Smartseal” software that controls the machines. It provides a user-friendly interface for monitoring sealing process and for reporting leakage measurements at required operating pressures.

Specifications

| Product Name | Gen2.1 FC00012 |

|---|---|

| Application | Commercial HVAC |

| Power Requirements | 3 x 120V AC 20A |

| External Requirements | Compressed Air (90 psi / SCFM) |

| Sealant Flow | 140CCM @ Pump Speed 1 100 CCM @ Pump Speed 2 63 CCM @ Pump Speed 3 25 CCM @ Pump Speed 4 0.4 – 2.2 gal / hour |

| Max CFM | 575 CFM (1150 with Add-on Fan) |

| Weight | N / A |

| External Dimensions | Fan Box – 21” L X 26” W X 18.75” H 5.92 ft3 |

| Measurement Range | 15 to 2000 CFM25 (Pduct > 5Pa) - Range is expandable by using booster fan boxes Fan boxes |

| Fan Static Pressure (Max) | 660 Pa (max 2.5”) |

Leaky Ductwork is Causing Critical Issues

To differentiate themselves in a competitive market, Energy Service Companies (ESCOs), engineers and contractors are looking for new ways to help facility owners reduce costs, modernize their infrastructure, and drive revenue. Research shows one of the clearest opportunities for improvement in commercial buildings is duct leakage.

The Right People, Process & Technology for Your Next Project

Our trusted team of experts and network of service providers work as a seamless extension of your project team. Using our comprehensive, four-phase process, and innovative duct sealing technology, we handle your airflow issues so you can focus on other project priorities.

PHASE 1

Audit & Evaluation

Data gathering and site inspection for an efficient and effective project plan.

Every building is different based on type, location and its HVAC system. With a thorough understanding of a building’s current state, we ensure an efficient and effective project timeline.

PHASE 2

Model & Plan

Quantifying ductwork leakage and running our energy model to ensure plan success.

The project implementation plan is part of each project’s quotation or bid documentation and is based on input from phase one.

The plan estimates energy savings from our duct leakage reduction. It is created using one of Aeroseal’s four different energy models. Duct leakage estimates can be converted for use in a project’s broader energy modeling.

PHASE 3

Repair, Clean, Sanitize & Seal

Customizing solutions to reach project goals and meet each building’s needs.

– Making sure the duct system doesn’t need repairs is critical to ensuring project results. Our team then determines if ductwork needs to be cleaned and sanitized before sealing.

– We pressurize your ductwork system, including ventilation shafts, heating and cooling shafts and other ductwork, to determine the amount of leakage.

– Using our non-invasive technology, we seal the ductwork to ensure the building’s HVAC system can operate at peak efficiency.

– In fact, Aeroseal duct sealing often eliminates the need to replace entire ductwork systems.

PHASE 4

Measurement & Verification

Tracking and verifying project work digitally before issuing a certificate of completion.

The Aeroseal software tracks results in real time. Once leak reduction goals have been reached, the results are recorded and a certificate of completion is printed showing before and after leakage amounts.