Aeroseal Equipment

State-of-the-art Automated Duct Sealing

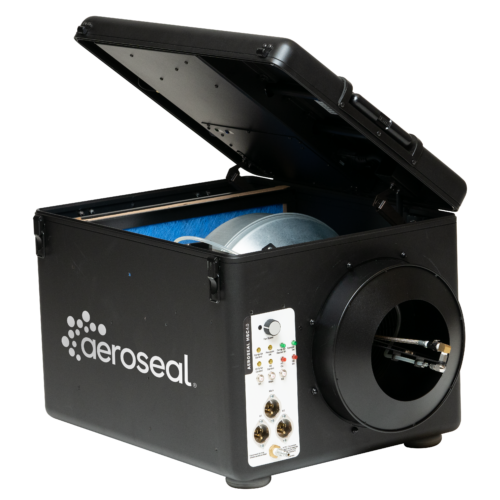

HomeSeal Connect 4.0

Equip your team with the Home Seal Connect 4.0 (HSC 4.0) from Aeroseal, the top choice for duct sealing. This piece of Aeroseal equipment is designed for ease of use and durability, handling the demands of your busiest season. It employs certified industry methods to eliminate duct leakage in any HVAC system, regardless of duct material. Our advanced technology measures pressure and airflow dynamically using a calibrated fan and intuitive software. The entire process is managed through the latest version of our air sealing software AeroSuite, providing real-time measurements and recordings of airflow and leakage

Specifications

| Product Name | Home Seal Connect 4.0 |

|---|---|

| Application | Residential, Light Commercial |

| Power Requirements | 3 x 120V AC 15A |

| External Requirements | Compressed Air (90 psi / 6 SCFM) |

| Weight | 70lbs |

| External Dimensions | 26” L x 21” W x 16” |

Expand Your Offerings & Opportunities

Key Benefits to adding Aeroseal

New Revenue Stream

Duct sealing is a service that applies to all of your customers. It creates opportunities to reengage existing customers and to find new ones.

Stand Out from Competitors

Stand out from competitors with the Aeroseal equipment. Offer a unique service that complements your existing offering.

Optimize Existing Resources

Duct sealing is easy to add on to an existing offering and doesn’t require new skills. It’s a complementary service like duct cleaning and energy efficiency services. You can build on your existing skills and equipment.

No “Slow Sales” Seasons or Labor Issues

Stay busy year-round by offering complete home solutions and offering a new career path and growth opportunity for your team.

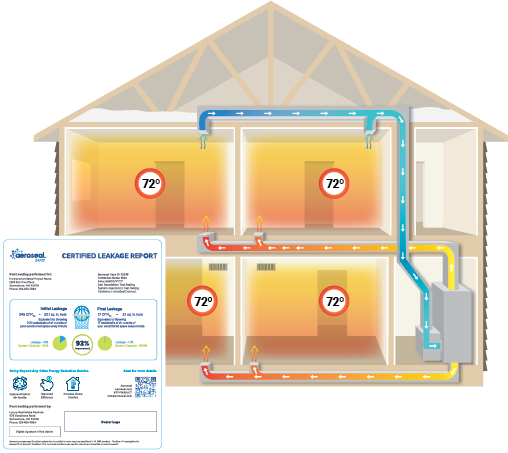

The Process Explained

Summarized in 3 Steps

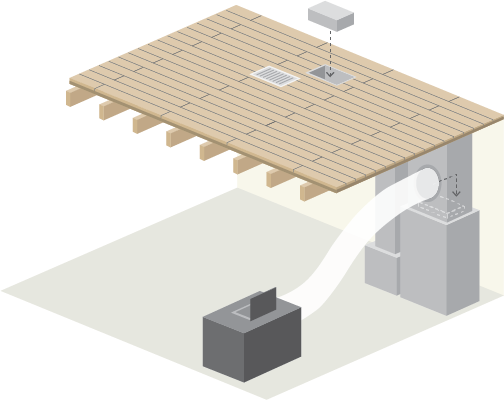

STEP 1: Prep & Test

Prepare System / Blocking

Registers are temporarily blocked to force air to escape through any leaks. Then, the air conditioning coil, fan, and furnace are temporarily blocked to prevent sealant particles from entering any sensitive components of the HVAC system.

Connect System to Ductwork

A small, temporary access hole is cut into the duct work, and a temporary flange is attached. Once the system is prepared, the Aeroseal equipment is connected to the ductwork using lay flat tubing.

Pretest Ductwork

The HSC 4.0 runs a pretest that pressurizes the duct system and provides a leakage reading on the computer. This will detect the exact amount of leakage in the duct system (the typical duct leakage detected in a home is 20 - 30% per the Department of Energy).

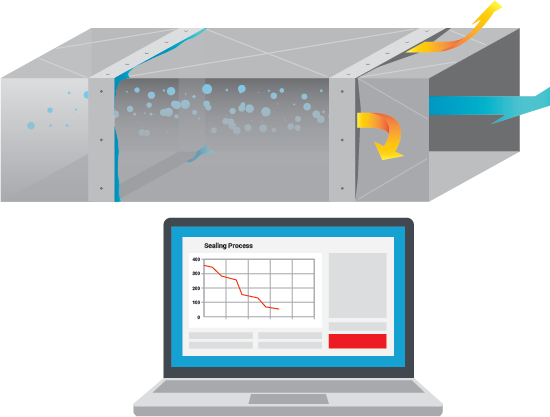

STEP 2: Seal & Measure

Leaks Are Found

The patented aerosol sealant is injected as a dry mist into the ductwork. Holes and cracks in the duct system are found by the pressurization.

Sealant Seals Ductwork

Sealant particles collect on the edges of holes and cracks in the ductwork to seal them from the inside.

Track & Record Progress

The software allows the technician to monitor progress in real-time and watch the minute-by-minute reduction in leakage.

STEP 3: Enjoy Comfort & Energy Savings

Verify Duct Sealing

Upon completion, the homeowner is presented with verifiable proof of the seal – a certificate generated by the Aeroseal equipment, with before and after results.

Results Customers Can See & Feel

In addition to a visual record of the work, customers feel the results almost immediately. Temperatures throughout the building even out, hot and cold spots are eliminated, and the HVAC system runs more efficiently. Homeowners will also notice improved indoor air quality and lower utility bills.

Show Customers The Results

Aeroseal's Certificate of Completion

Aeroseal’s software generates an analysis summarizing key points of the duct sealing process.

Before and after leakage test results

A graph showing progress during the process

Heating and cooling capacity improvement

This visual record for the customer verifies the duct sealing process was a success. And it ensures customers can see the difference immediately before feeling the improved indoor comfort and getting a lower utility bill.

FAQ

Start Using Aeroseal Today

Seize the opportunity and start the conversation now.