Aeroseal Equipment

Engineered & Designed for New Construction HVAC

Home Seal Xpress

Your team will use the Home Seal Xpress (HSX) duct sealing system from Aeroseal, a durable and user-friendly tool that ensures minimal duct leakage in any HVAC system. This piece of Aeroseal equipment applies certified methods to measure pressure and airflow dynamically, providing real-time data through its software. It includes a seal certificate verifying duct leakage results, which can be presented to code inspectors.

Specifications

| Product Name | Home Seal Xpress |

|---|---|

| Application | New Construction |

| Power Requirements | 3 x 120V AC 15A |

| External Requirements | N / A |

| Sealant Flow | 57 CCM (0.09 gal/hr) |

| Max CFM | 1000 CFM |

| Weight | Fan Box – 58lbs Pump Box – 34lbs |

| External Dimensions | Fan Box – 32.5” L X 15” W X 16.5” H 4.65 ft3 Pump Box - 19” L X 13” W X 15” H 2.14 ft3 |

Why Start Using the HSX On Your Jobs?

Typical Job Costs Using Aeroseal

Manual vs. Air Sealing

The costs of Aerosealing are as good as or better when including labor to hand-sealing with mastic. Aeroseal equipment means not fail inspections, and can used in place of an inspection in several states.

| Job Profitability | ||

| Per Day (3 seals) $1100 Retail | Per Month (30 seals) | |

|---|---|---|

| Total Revenue | $3,300 | $33,300 |

| Total Expenses | $1,428 | $14,280 |

| Expenses | $1,872 (57%) | $18,720 (57%) |

| Job Cost | ||

| Per Job | ||

| Labor/HR | $40 | |

| Total Labor/HR | $46 | |

| Prep Time | 0.5 HR | |

| Sealing Time | 1 HR | |

| Breakdown/Clean up | 0.5 HR | |

| Total Job Time | 2 HR | |

| Total Labor Cost | $92 | |

| Material Cost | $175 | |

| License Fee** | $209 | |

| Total Expenses | $476 | |

Utah Code Rescue

Case study | Salt Lake City, Utah

The job was progressing like any other. The builder’s usual HVAC contractor was installing sheet metal ductwork and hand-sealing joints with mastic as they usually do.

After the first pass of mastic work, the ductwork failed inspection. After a 2nd pass, the ductwork still wasn’t passing, with over 360 CFM of leakage, or 12 CFM per 100 ft2, leaking through the ductwork after 8 hours of labor and $600 of inspection fees. The builder was in trouble. To avoid rebuilding the ductwork, they called Aeroseal-dealer Airlock, LLC, to save the project’s timeline.

After only 60 minutes of, duct leakage was brought down to 20 CFM, or <1 CFM per 100 ft2, easily passing inspection.

The Process Explained

Summarized in 3 Steps

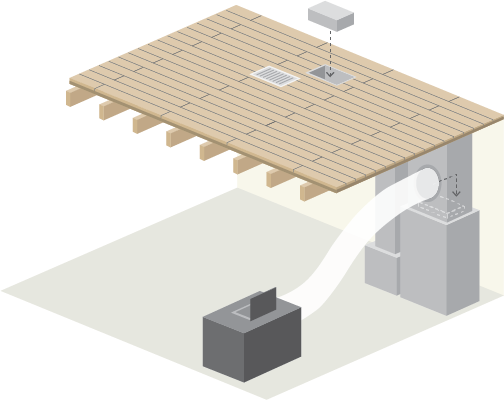

STEP 1: Prep & Test

Prepare System / Blocking

Registers are temporarily blocked with foam plugs to force air in the ductwork to escape through any leaks. Then the air conditioning indoor coil, fan, and furnace are temporarily blocked with a foam plug to prevent sealant particles from entering this part of the HVAC system.

Connect System to Ductwork

Once the system is prepped, the Aeroseal equipment is connected to the ductwork using lay flat tubing. A small, temporary access hole is cut into the duct work, and a temporary collar is attached. One end of the tubing connects to the collar; the other end connects to the Aeroseal device.

Pretest Ductwork

The Aeroseal system runs a pretest that pressurizes the duct system and provides a leakage reading on the computer. It will detect the exact amount of duct leakage in the duct system (the typical duct leakage detected in a home is up to 40%).

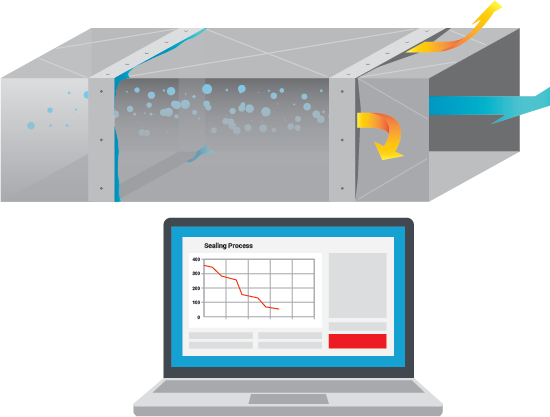

STEP 2: Seal & Measure

Leaks Are Found

The patented aerosol sealant is injected as a dry mist into the ductwork. Holes and cracks in the duct system are found by the pressurization.

Sealant Seals Ductwork

Sealant particles collect on the edges of holes and cracks in the ductwork to seal them from the inside.

Track & Record Progress

Aeroseal system software allows the technician to monitor progress in real-time and watch the minute-by-minute reduction in leakage.

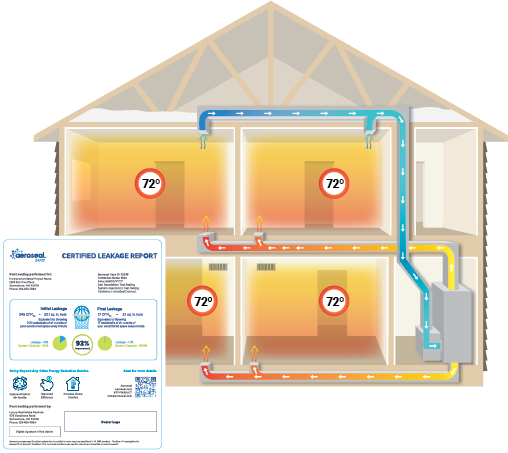

STEP 3: Enjoy Comfort & Energy Savings

Verify Duct Sealing

Upon completion, the homeowner is presented with verifiable proof of the seal – a certificate is generated by the equipment with before and after results.

Results Customers Can See & Feel

In addition to a visual record of the work, customers feel the results almost immediately. Temperatures throughout the building even out, hot and cold spots are eliminated, and the HVAC system runs more efficiently. Homeowners will also notice improved indoor air quality and lower utility bills.

Show Customers The Results

Aeroseal's Certificate of Completiong

Aeroseal’s leak sealing software generates an analysis summarizing key points of the duct sealing process.

Before and after leakage test results

A graph showing progress during the process

Heating and cooling capacity improvement

This visual record for the customer verifies the duct sealing process was a success. And it ensures customers can see the difference immediately before feeling the improved indoor comfort and getting a lower utility bill.