No matter what kind of building you own, it’s almost certainly going to have an HVAC system in place. The HVAC system of any building is designed to maintain the indoor air and keep it at a comfortable level.

Not only does this mean heating or cooling the air to the level set by whoever is operating the thermostat, but it also means filtering air and keeping the indoor air of your building free from outside pollutants that might contaminate it.

If the HVAC duct system is in perfect working order, it will achieve both of these goals with no problem. If it’s not, however, then not only could harmful pollutants enter the indoor air space of your building, but you’ll also be wasting energy and losing what could be a large sum of money each month on energy bills. This is why air duct leakage testing is so important.

The only way to truly measure the effectiveness of your HVAC system is to seal it off and use special equipment to run a pressurized test and see if any air is leaking through holes in the ductwork.

This is a procedure that is done during the rough-in process, but it can be performed throughout various stages of construction.

It can also be performed long after construction has been completed if you suspect your ductwork may have been damaged or compromised in some way. This is a very common occurrence, and most buildings today suffer from some percentage of duct leaks.

In case you weren’t aware of the overall importance of having an air duct leakage test performed on your HVAC system, let’s go over a few of the details such as how it’s done and what to do with the results when it’s completed.

Duct Leakage Test Comes in 2 Varieties

There are two main types of air duct leakage tests:

1. TDL

TDL stands for “total duct leakage.”

It measures the total amount of leakage you have going into both conditioned and unconditioned spaces.

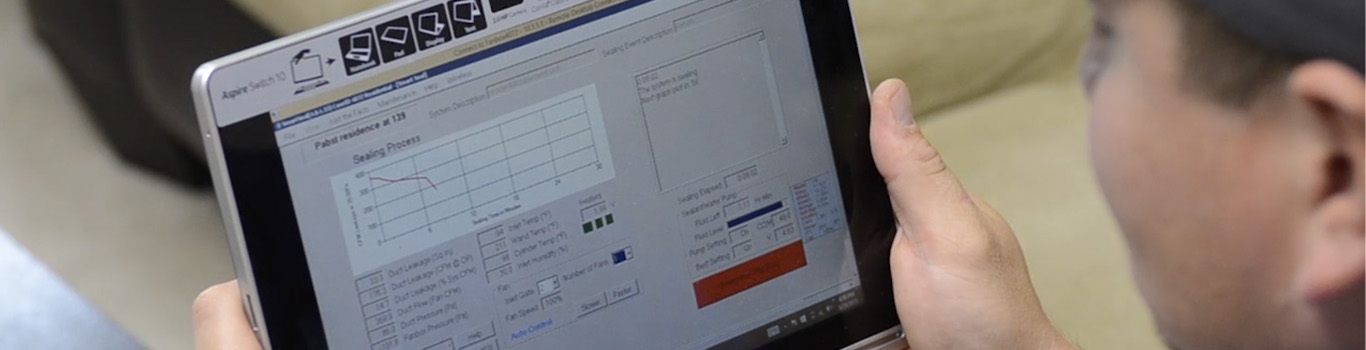

TDL testing is performed with a duct leakage tester, which is a diagnostic tool that is used for measuring the airtightness of ventilating, air heating, and air conditioning ductwork.

This tester is made up of a calibrated fan that is used to measure airflow rate, as well as a pressure sensing device that will be able to measure the amount of pressure that is put out by the fan flow.

The combination of fan flow measurements and pressure is used to determine exactly how airtight the ductwork is.

Your return air grills or supply registers will be sealed off with HVAC tape, with one register being left unsealed. This register will have a calibrated fan hooked up to it and pressure will be monitored in the ductwork while the calibrated fan delivers air into your system.

As the device blows air into the system, pressure will build up and force air out through any leaks that might be present. The tighter a system is, the less air will be needed to facilitate a change in ductwork pressure.

TDL tests can be done by either pressurizing or depressurizing the ductwork system, but depressurization is risky because it can suck in contaminants from the outside.

2. LTO

LTO stands for “leakage to outside.”

LTO testing measures only the amount of leakage you have going into unconditioned spaces, like uninsulated crawlspaces, unconditioned attics, and similar areas.

LTO testing can be performed in a similar way to TDL tests but with the house being pressurized at the same time as the ductwork so that technicians can measure the amount of airflow needed to equalize the pressure.

Which Duct Leakage Test Method is More Effective?

While both methods are effective at measuring leakage, LTO testing is more effective in improving energy efficiency because that air is essentially leaking directly out into nowhere, while air leaking into conditioned spaces is still technically going into the areas you want it to, just with the possibility of contaminants getting in through the leaks and compromising the air in the entire building.

Aeroseal’s Duct Leakage Test Provides Real Results