The Complete Guide to Aeroseal’s Sealant

Aeroseal Duct Seal Proven Safe and Effective by Exacting International Standards

Aeroseal’s leak sealing technology can be used across residential and commercial buildings for HVAC duct sealing and air sealing. And while these are all unique applications of our award-winning technology, there is one common thread – our sealant.

This may be why one of our most frequently asked questions, regardless of technology or application, is about our sealant. The following guide answers questions across several key areas — as they pertain specifically to Aeroseal’s Duct Seal sealant for use in Residential and Commercial HVAC Duct Sealing.

- Basic Composition & Physical Properties

- Efficacy & Safety Certifications

- How Does It Seal Leaks?

- Sealant vs. Mastic

- Additional Resources

BASIC COMPOSITION & PHYSICAL PROPERTIES

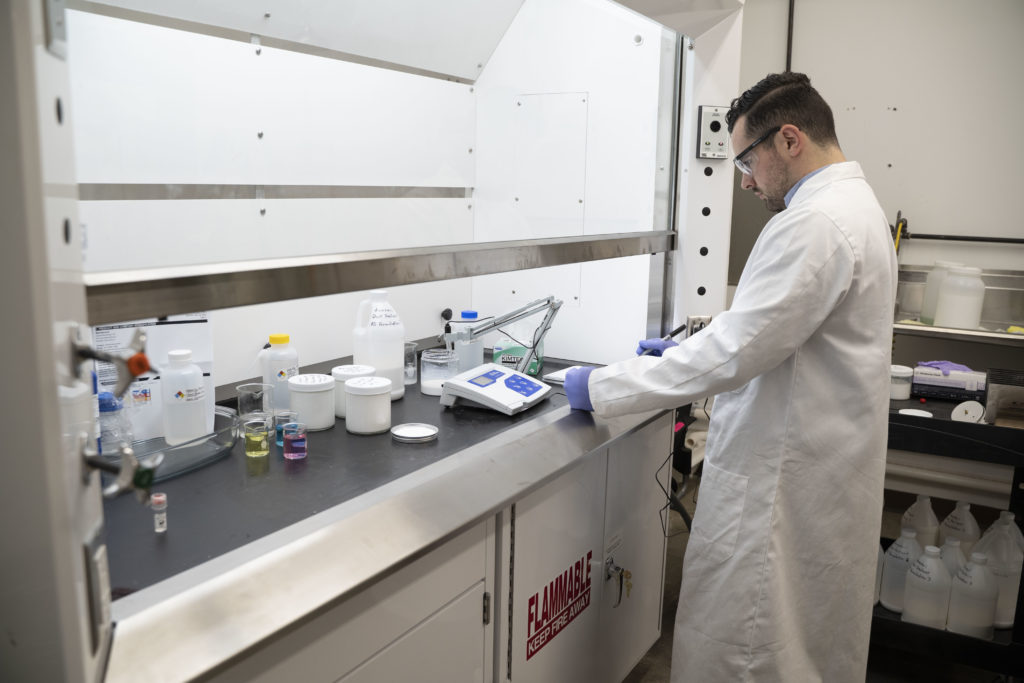

The Aeroseal Duct Seal sealant is, at its simplest, a milky white liquid. An emulsion of water and vinyl acetate, it is stable, non-toxic, and non-flammable. The vinyl acetate comes from ethylene through the reaction of oxygen and acetic acid, which combusts into carbon oxides CO and CO2.

Composed of Ingredients Commonly Found in Everyday Objects

Many of these same ingredients are also found in pacifiers and chewing gum. Vinyl acetate, for example, is used in the adhesive that seals an envelope you lick before closing as well as children’s glue.

While there is a small amount (0.35% by weight) of volatile organic compounds (VOCs), it is barely traceable and not a cause for concern. The VOC content is approximately 0.2% vinyl acetate monomer (VAM), 0.1% 2-ethylhexanol (2EH), and 0.05% acetaldehyde. Air scrubbers remove any remaining VOCs upon completion of the seal and all are extinguished within two hours after applying Duct Seal.

Additionally, there are salts, stabilizers, and surfactants that are present in trace amounts (below 0.01% by weight) that are classified as proprietary. However, the sealant’s makeup can be divided into four stand-alone components:

- Water: 50%-70%

- Acrylic polymer: 20%-40%

- Silica, amorphous: 1%-5%

- Propylene glycol: 1%-5%

EFFICACY & SAFETY CERTIFICATIONS

Aeroseal’s Duct Seal is proven safe and effective. It’s been used to seal more than 200,000 projects across the globe, in everything from homes, hospitals, and schools to government facilities, hotels, and offices.

Aeroseal has a ten-year warranty – but a durability of 40 years. Accelerated testing conducted at Lawrence Berkeley National Laboratory showed no sign of deterioration in Duct Seal. In fact, it continued to hold a seal well past the life span of tape and mastic. So while the warranty covers the contractor for 10 years, it has been proven to last for decades.

And when it comes to safety, Aeroseal Duct Seal has earned more than eight different quality and safety certifications.

| Certification | Organization |

|---|---|

| 700: National Green Building Standard | International Code Council (ICC) |

| Standard E2342-10 Leakage Reduction & Durability | ASTM International |

| WELL Building Standard Certified | The International WELL Building Institute |

| 181 A: Closure Systems for Use with Rigid Air Ducts 181 B: Closure Systems for Use with Flexible Air Ducts & Air Connectors 555: Fire Dampers 555S: Smoke Dampers 723: Fire Endurance & Surface Burning of Caulking Materials |

Underwriters Laboratories (UL) |

| Green Building Assessment Protocol | American National Standards Institute (ANSI) |

| Green Certification in Energy Efficiency | National Green Building Standard (NGBS) |

| LEED V4 Low-Emitting Materials | U.S. Green Building Council (USGBC) |

| Standard Method V1.2 2017 for VOC Emissions | California Department of Public Health (CDPH) |

HOW DOES IT SEAL LEAKS?

To prepare a home’s ductwork to be sealed, the HVAC system’s furnace and vents must be blocked off and an injection point must be created in the ductwork. Layflat tubing connects the Aeroseal duct sealing system to the ductwork.

Once the system begins the process, the Duct Seal is superheated. This atomizes the sealant into a dry fog of 4-10 micron-sized particles while vaporizing 95% of VOC and 100% of water. Click here to learn more details about the atomization process.

Injecting atomized sealant into pressurized HVAC ductwork applies physics to sealing leaks instead of unreliable and inconsistent manual processes. Forced air escapes through otherwise undetectable and inaccessible leaks as big as 5/8” and as small as a human hair. Sealant particles are drawn to these leaks with the escaping air. Particles build upon themselves to block and cover each hole.

Duct Seal dries with a texture like vinyl. After drying, it remains rubbery and bendable. Its elasticity allows it to evade any abrasion it might encounter during its lifetime. This makes weakening and deterioration of the sealant unlikely.

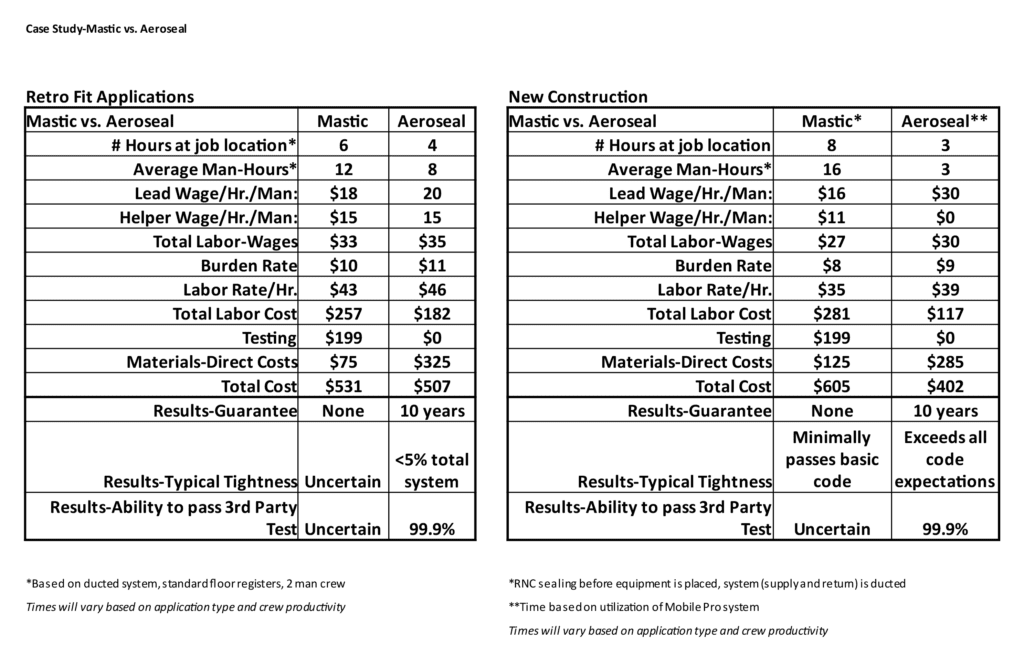

SEALANT vs. MASTIC

First, it’s simply impossible to manually reach all the leaks in ductwork that has already been installed. The overwhelming majority of the duct is hidden or virtually impossible to access for manual sealing. If you want to have a real impact on energy savings and HVAC performance, you’ll need to reach and seal leaks throughout the entire duct system.

Even in new homes, we hear again and again about new ductwork that has been installed and meticulously sealed by hand, yet continues to underperform due to leaks. And if the manual sealing passed code when first installed, it often fails just months later following climate changes or other external factors. With Aeroseal, you also get documentation of results. The process begins with a computerized analysis of the ductwork and ends with a post-test. You and your customers get a printout of the results that highlight the before and after results. Lastly, it’s just better. Studies comparing the two show that Aeroseal is 60% more effective and 30% less expensive than manually sealing ductwork.

Aeroseal is applied automatically, whereas mastic is done manually. Because of this, mastic requires manual labor, but the Aeroseal machine handles it technologically. Human error is therefore close to zero. Another bonus is that mechanical stability and adhesion to LSE (low surface energy) substrates are high with Aeroseal, meaning it can target the smallest of leaks.

Masking with mastic is cumbersome and takes a considerable amount of time and effort with no guarantees on hidden holes being detected and sealed, whereas Aeroseal targets and seals these hidden holes. Safe and easy to administer, it is hands-off and automatic.

Taking cost into consideration, the labor cost of a new construction mastic job comes to approximately $281, but for an Aeroseal job, it is approximately $117. The number of labor hours needed for a mastic job is roughly 16 hours. For Aeroseal, it is roughly 3 hours. This results in 30% less labor hours needed. Testing is an additional $199 for mastic.

Considerations When Sealing and Safekeeping

Our sealant is acrylic as well as thermoplastic. It is functional at temperatures between -20 degrees F and 480 degrees F with a shelf life of 2 years. For storage, it is best preserved in a dry, protected space with temperatures from 32 to 120 degrees F. It is resistant to moisture, mold, and mildew, which prevents organic contamination in storage (UL 181). Along with this, it meets test criteria stating that it does not become vulnerable to humidity and erosion (UL 1381 and UL 181). Exposure to strong oxidants, such as liquid chlorine, sodium hypochlorite, and calcium hypochlorite should be avoided.

There should be less than 1/8 an inch of debris on the ductwork’s interior for the formula to set and dry properly. It has a seal rate of 0.4 to 2 gallons per hour. The amount of sealant that is deposited is as much as needed, no more no less. This eliminates waste, which makes cleanup a walk in the park.

For any additional questions about Aeroseal’s Duct Seal sealant, additional resources are below.

Or click here to contact us directly.

ADDITIONAL RESOURCES